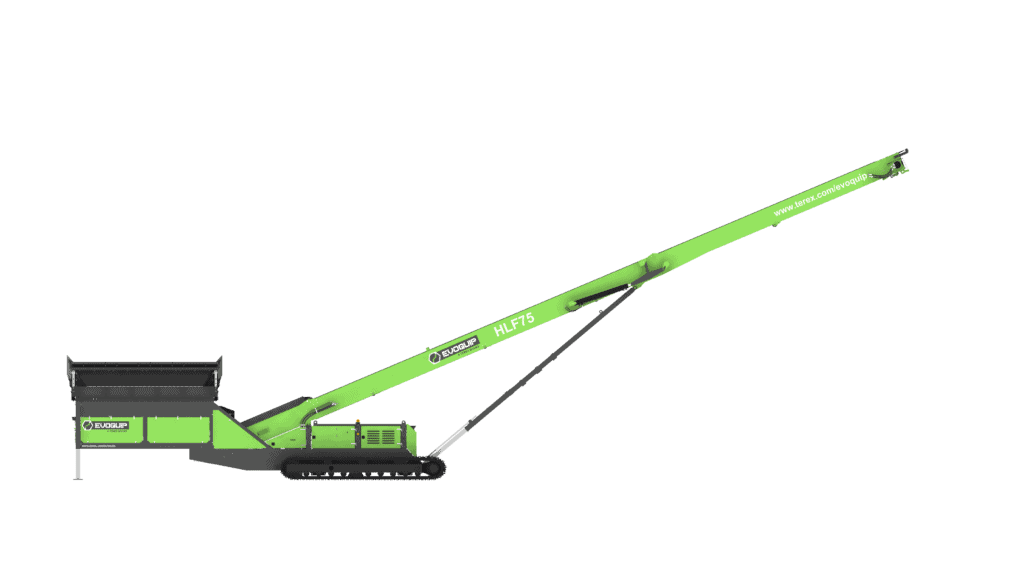

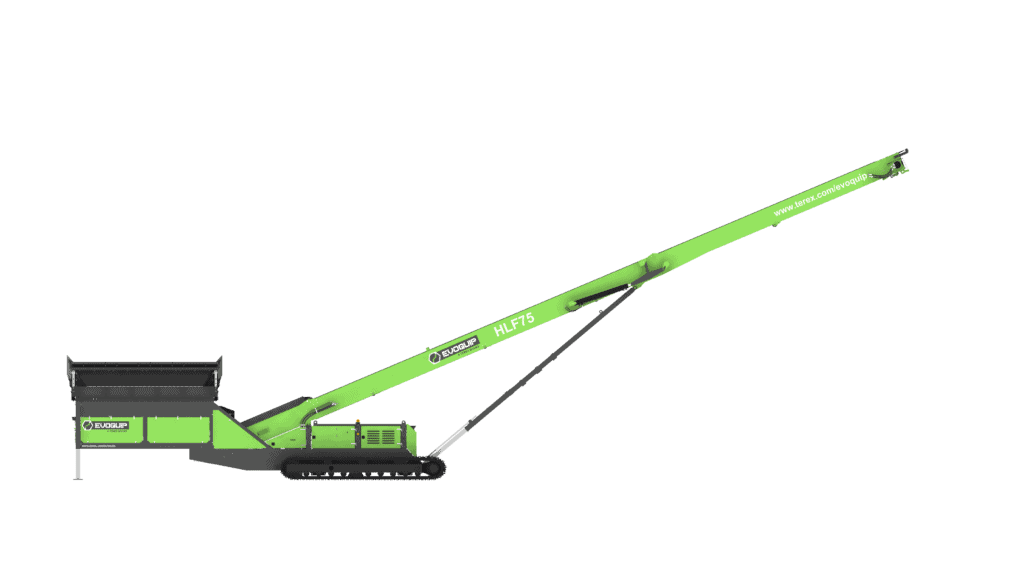

Terex HLF 75 Conveyor

The Evoquip HL75 High Level Feeder Conveyor allows the operator to directly discharge from wheel loaders to eliminate the double handling of material on site.

Mobile Screening and Crushing NZ are proud distributors of Terex conveying systems throughout New Zealand. Established in 1995, MSC’s 25 years in supplying equipment to the extractive and recycling industries enables them to recommend with confidence the most suitable conveying solution for your requirements.

The Evoquip HL75 High Level Feeder Conveyor allows the operator to directly discharge from wheel loaders to eliminate the double handling of material on site.

The TC 75R Tracked Radial Conveyor offers unrivalled stock piling capacity with a 75-foot working length and a max discharge height of almost 36 foot.

The TC100 features a conveyor length of (30m) and a capacity of up to 600 tph. With built in hydraulics adjustment are quick and easy with a maximum angle of 28 degrees and max height of 14.3m.

The TC80 features a conveyor length of 80ft (23.5m) and a capacity of up to 400 tph. It hydraulically folds for transport and can be loaded into a single container thanks to its for roll on roll off design.

The TC65-T features a conveyor length of 65ft (20m) and a capacity of up to 400 tph. The TC-65 is a self-powered 65ft tracked stockpiler with impressive features and conveying capacities.